Skype

hualianpm

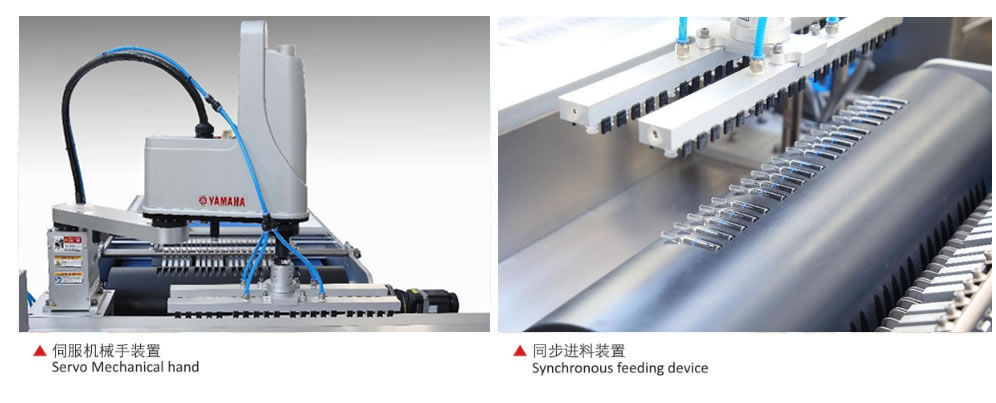

This production line is suitable for medicines, especially oral liquids, ampoules blister packaging and automatic cartoning. It can automatically detect and reject waste, the robot automatically adds the bottle, and the robot automatically releases the straw. The high-speed automatic cartoning machine puts the medicine board and instructions into the carton, seals the box and prints the batch number. The whole process is fully automatic packaging, which can achieve the purpose of saving labor on the site. High automation and high cleanliness are more in line with GMP requirements.

Technical parameters:

| model | DPB-350JV | |

| Packaging Materials | Standard PVC Rigid Sheet | 0.15-0.5 × 350mm |

| Standard PTP foil | 0.02-0.035×350mm | |

| The diameter of the reel is | 70-76mm | |

| punching frequency | 16-26 times/min times/min | |

| Maximum molding area | 150×350mm (can be designed according to user needs) | |

| Maximum forming depth | 26mm | |

| Traction stroke | Punch Punch: 20-160mm (can be designed according to user needs) | |

| total power | 380V/50Hz 12KW | |

| Air consumption | 12 m3/h (self-provided) Pressure: 0.6-0.8Mpa | |

| mold cooling | Tap water or circulating water 60L/h | |

| Dimensions | 4500×940×1800mm | |

| Total Weight | 3000Kg | |